ATF Boru: How It’s Shaping the Future of Pipeline Technology

The world of pipeline technology is evolving at a rapid pace, driven by innovations that promise to enhance efficiency and safety. At the forefront of this revolution is ATF Boru, a groundbreaking solution that’s capturing attention across various industries. As energy demands grow and environmental concerns become more pressing, companies are looking for advanced materials that can withstand challenges while maintaining cost-effectiveness. Enter ATF Boru—an innovative player in the pipeline sector that’s shaping how we think about infrastructure. Join us as we explore what makes ATF Boru a game-changer in pipeline construction and its potential impact on the future of this essential industry.

What is Pipeline Technology?

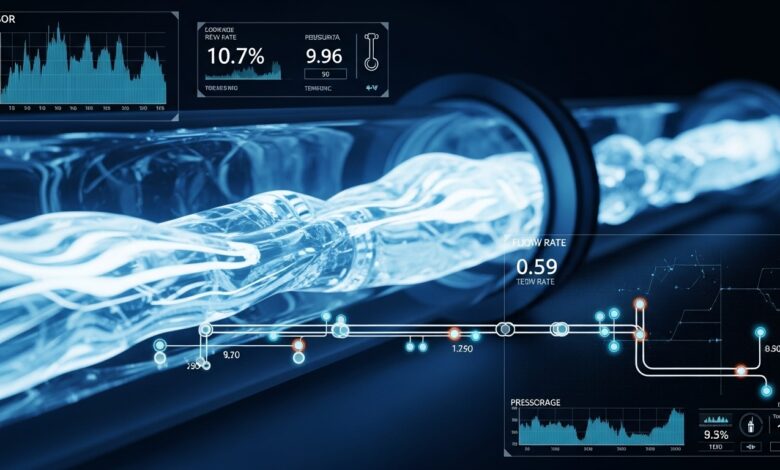

Pipeline technology encompasses the systems and methods used to transport fluids, gases, and other materials from one location to another. This field integrates engineering principles with innovative solutions to ensure efficiency and safety.

At its core, pipeline technology involves designing pipes that can withstand various pressures while minimizing leaks. Materials selection is crucial; modern pipelines often utilize advanced composites or high-grade steel for enhanced durability.

Monitoring systems have become integral as well. Sensors track flow rates, pressure changes, and potential leaks in real-time. This data allows operators to act swiftly, reducing downtime and environmental risks.

The evolution of pipeline technology reflects broader trends towards sustainability. Companies are now focused on creating eco-friendly alternatives that minimize their carbon footprint while maintaining operational integrity. As industries grow more interconnected, effective pipeline solutions will play a pivotal role in global infrastructure development.

The Benefits of Using ATF Boru in Pipeline Construction

ATF Boru offers numerous advantages in pipeline construction that set it apart from traditional materials. Its lightweight composition makes installation more efficient, reducing labor costs and time.

The durability of ATF Boru is another significant benefit. Resistant to corrosion and environmental factors, it ensures a longer lifespan for pipelines, minimizing the need for frequent replacements.

Flexibility is key when dealing with varying terrains. ATF Boru’s adaptability allows engineers to navigate complex landscapes without compromising structural integrity.

Moreover, this innovative material boasts superior flow characteristics. It enhances fluid transport efficiency, resulting in reduced energy consumption during operation.

Safety also gets a boost with ATF Boru. Its robust design lowers the risks associated with leaks or failures, providing peace of mind for operators and communities alike.

Case Studies: Real-Life Examples of Successful Implementations

One notable case study involves a major oil company that faced corrosion issues in their pipeline infrastructure. By switching to ATF Boru, they not only extended the lifespan of their pipelines but also reduced maintenance costs significantly.

Another example comes from a water utility provider. They implemented ATF Boru technology and noticed remarkable improvements in flow efficiency. The enhanced durability meant fewer leaks and disruptions for local communities.

In an industrial setting, a manufacturing plant adopted ATF Boru for transporting chemicals. The result was safer operations with minimal risk of environmental contamination due to its robust design.

These real-life applications illustrate how versatile and effective ATF Boru can be across various sectors. Each case reveals unique challenges met with innovative solutions that have proven successful over time.

Future Potential and Forecast for ATF Boru

The future for ATF Boru looks promising as industries increasingly prioritize efficiency and sustainability. As global demand for energy grows, innovative pipeline solutions will be crucial. This material stands out due to its durability and resistance to corrosion, making it a preferred choice.

With advancements in technology, manufacturers are likely to explore new applications for ATF Boru beyond traditional uses. The potential expansion into renewable energy pipelines could revolutionize how resources are transported.

Forecasts suggest that investments in infrastructure incorporating ATF Boru will rise significantly. Governments and private sectors alike recognize the advantages of this modern solution over conventional materials.

Additionally, environmental regulations may drive further adoption. Companies aiming to meet stricter standards will find ATF Boru offers a competitive edge while minimizing ecological impact.

Comparison with Traditional Pipeline Technologies

Traditional pipeline technologies have long relied on materials like steel and concrete. While effective, these options often come with significant drawbacks, including corrosion and high maintenance costs.

ATF Boru stands out by using advanced composite materials that resist corrosion. This durability translates to lower upkeep expenses over time. Additionally, ATF Boru’s lightweight nature makes installation faster and less labor-intensive.

Another notable difference is flexibility in design. Traditional pipelines are rigid, limiting their adaptability in various terrains or environments. In contrast, ATF Boru can be tailored to fit specific project needs more easily.

Moreover, the environmental footprint of traditional methods tends to be larger due to resource-heavy production processes. ATF Boru promotes sustainability through its efficient manufacturing techniques and longer lifespan.

This modern approach positions ATF Boru as a game-changer amidst conventional solutions while addressing some longstanding industry challenges effectively.

Conclusion

The landscape of pipeline technology is evolving, and ATF Boru stands at the forefront of this transformation. By integrating innovative materials and advanced engineering practices, it not only enhances efficiency but also promotes sustainability in construction.

As industries increasingly turn their attention towards environmentally friendly solutions, ATF Boru offers a promising alternative to traditional methods. The real-life case studies showcase its potential for superior performance under various conditions.

Looking ahead, the future appears bright for ATF Boru as it continues to shape the industry standards. Companies seeking reliable and effective pipeline solutions should consider adopting this modern approach to meet both current demands and future challenges.

Embracing ATF Boru could be a pivotal move in redefining how we think about pipelines—ensuring they are strong, efficient, and eco-friendly while paving the way for advancements that benefit everyone involved.